Autonomous Mobile Robots (AMR)

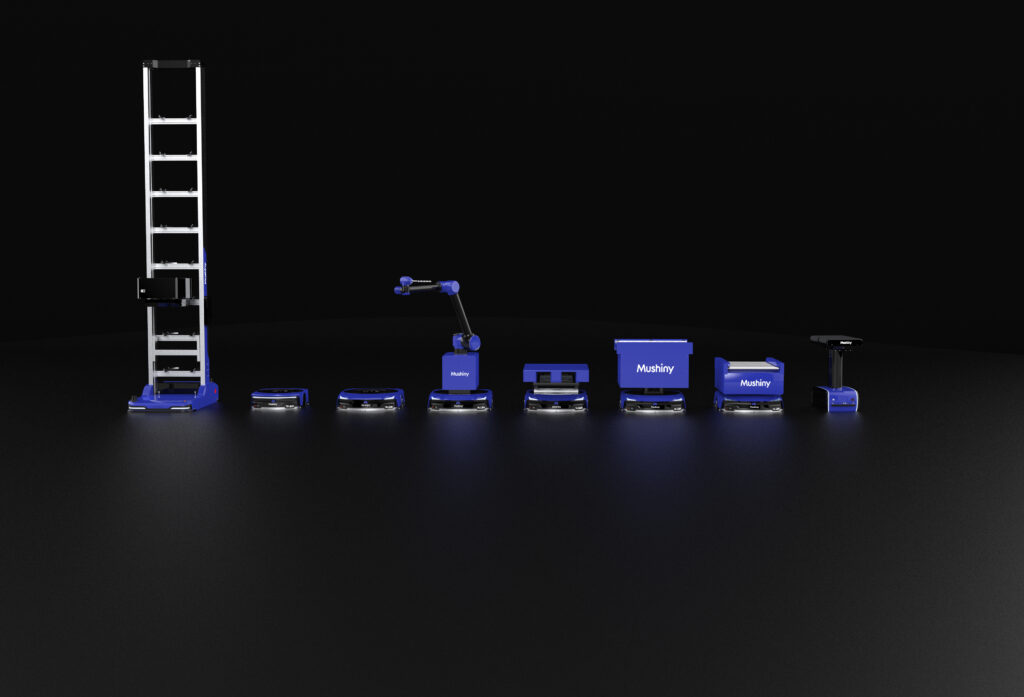

Material Flow Technologies is a proud partner with Mushiny AMR’s! Mushiny AMR’s are the first platform-based robot series in the industry.

Our customized solutions are equipped with world-class AI algorithms. We provide highly-usable and reliable robots and systems for warehousing and intralogistics. Our products and system platforms deliver value for various sectors such as e-commerce, manufacturing, distribution, warehousing, and etc. Moreover, our technology goes beyond efficiency improvement and focuses on optimizing the experience of human-device interaction.

Utilizing AMR's

Autonomous Mobile Robots (AMR) are indeed widely used in distribution and manufacturing environments to improve efficiency and streamline operations. These robots are designed to autonomously navigate through the facility, transporting goods and materials between different locations. Here are some key points about AGV robots in distribution centers:

Material Handling: AMR’s are primarily used for material handling tasks in distribution centers. They can transport pallets, racks, bins, and other types of containers, carrying goods from one location to another within the facility.

Navigation: AMR’s use various navigation methods to move around the distribution center. Common navigation methods include laser guidance, magnetic tape or markers on the floor, or even computer vision systems that allow the robot to perceive its surroundings.

Flexibility: AMR’s are designed to be versatile and adaptable to different environments. They can navigate through narrow aisles, avoid obstacles, and handle changes in the environment. Some AMR’s are also equipped with robotic arms or lift mechanisms to perform additional tasks like loading and unloading.

Integration with Warehouse Management Systems (WMS): AMR’s are often integrated with WMS software to optimize operations. The WMS controls and coordinates the movement of AMR’s, assigns tasks, and monitors their progress. This integration allows for real-time tracking, inventory management, and efficient task allocation.

Benefits: AMR’s offer several advantages in distribution centers. They can significantly reduce manual labor and human error, improve operational efficiency, increase throughput, and enhance safety by reducing accidents and injuries. AMR’s also offer the flexibility to scale operations based on demand fluctuations.

Collaboration with Humans: In many cases, AMR’s work collaboratively with human workers in distribution centers. For example, they can transport heavy or bulky items, while human workers perform more complex tasks such as order picking or quality control. This human-robot collaboration improves overall productivity and efficiency.

Continuous Development: The field of AGV robotics is continuously evolving. Newer technologies such as machine learning, computer vision, and artificial intelligence are being integrated into AMR systems, enabling them to make intelligent decisions, adapt to dynamic environments, and optimize their routes.

Overall, AMR’s play a crucial role in enhancing the efficiency and productivity of distribution centers by automating material handling tasks and streamlining operations. We are always looking for new ways to apply Mushiny technology. As an integrator of system solutions, we will consider all applications and apply the best available technology to meet the challenge. We are proud to be able to offer the Mushiny as one of the best products in the AMR category.